Product Introduction

In the field of automotive manufacturing, horizontal machining centers are mainly used for processing large, heavy and complex automotive parts. These components usually have strict requirements for dimensional accuracy, shape accuracy and surface roughness. With its high precision, high rigidity and high efficiency, the horizontal machining center can realize the precise machining of auto parts. For example, it can be used to process automotive engine blocks, cylinder heads, transmission housings, brake system parts and other key components. The processing quality and accuracy of these parts are directly related to the performance and safety of the vehicle.

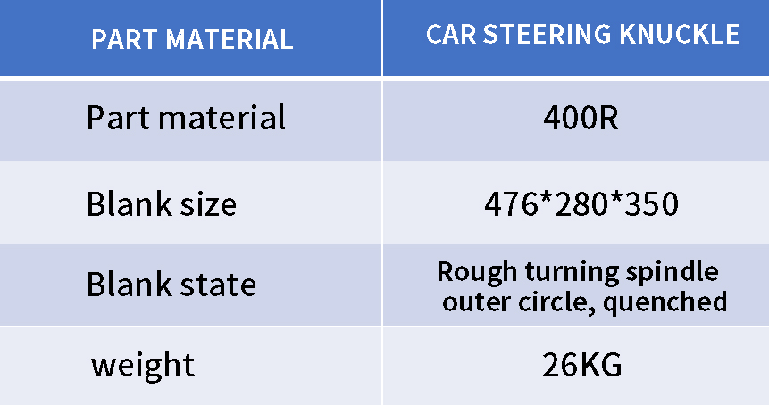

Solution Detail

NEVs, as the development trend of automobile in the future, the processing technology of its critical components has become particularly important.

The core components of NEVs such as batteries, motors and electronic controllers have high requirements for the precision of mechanical processing and need support from many aspects including CNC machine tools, automation equipment and advanced processing technology.

CASE1:

Requirements for the automotive parts industry:

High stability:

High efficiency:

High precision.

Highly automated:

Factory Showcase:

Processing process:

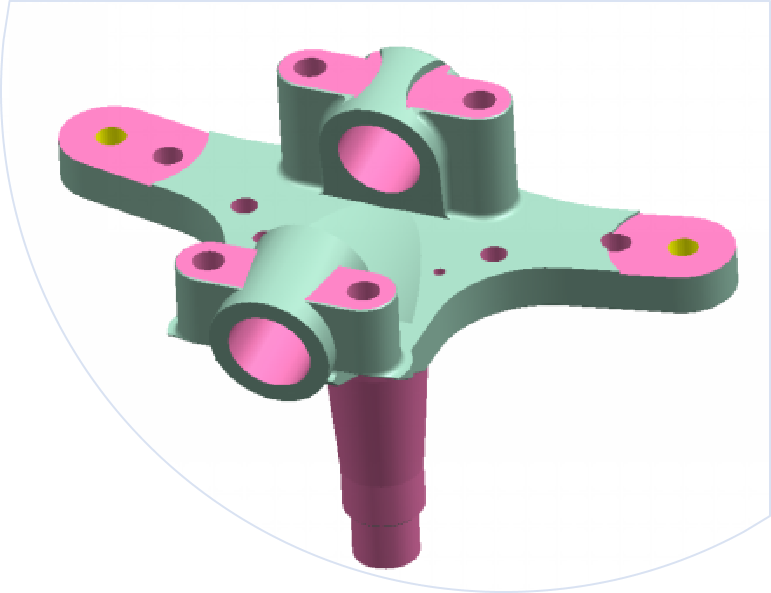

CASE2:

OP10: Use φ80 disc milling cutter to process 8 step surfaces.

Processing time 2.35min

OP20: Use φ20.5 compound drill, M22 tapping, and boring tool to process flange hole.

Processing time: 2.5min

OP30: Use φ6.8/φ18/φ14.5 compound drill and M22/M8 tap to process holes and threads

Processing time: 2.45min

OP70: Use φ63 disc milling cutter, φ10 center hole, φ6.5 drill to process plane and cross hole

Processing time: 2.5min